Detailed performance metrics for the AmbaSat-1 3U CubeSat platform and hosted payload interfaces

| Subsystem | Specification |

|---|---|

| Form Factor | Standard 3U CubeSat (100 x 100 x 340 mm). Open frame structure |

| Payload Volume | Up to 2.5U available for hosted experiments |

| Power Generation | 5x1U Solar Array units each providing 2.4W with an approximate 12W Peak |

| Payload Power | 3.3V and 5V regulated rails (Up to 1A per slot) |

| Communications | Internal: Low-power LoRa link between AmbaSat-1 ChipSats and onboard gateway (within open 3U frame). External: UHF downlink from CubeSat gateway to ground station. No direct ChipSat-to-Earth link |

| Pointing Accuracy | No active ADCS on AmbaSat 3U |

| Environmental | Electronics qualified for −40 °C to +85 °C. 3U open-frame structure (not sealed), supporting internal LoRa propagation. Actual in-orbit temperature range defined by platform environment |

AmbaSat-1 is a 3U CubeSat payload for a 30-day Low Earth Orbit (LEO) mission, offering SMEs an affordable hosted-payload platform to trial and de-risk new sensors and IoT applications in space. The mission showcases intra-satellite LoRa communication as a practical mechanism for aggregating data from multiple experiments inside a shared CubeSat.

AmbaSat-1 gives organisations a practical, low-cost route to in-orbit demonstration. Each customer experiment is hosted on a dedicated ChipSat, mounted on a shared 3U platform with defined power, data and mechanical interfaces. We handle integration, launch and operations, then return your experiment data via our secure ground infrastructure so you can focus on proving the business case, not managing the space segment.

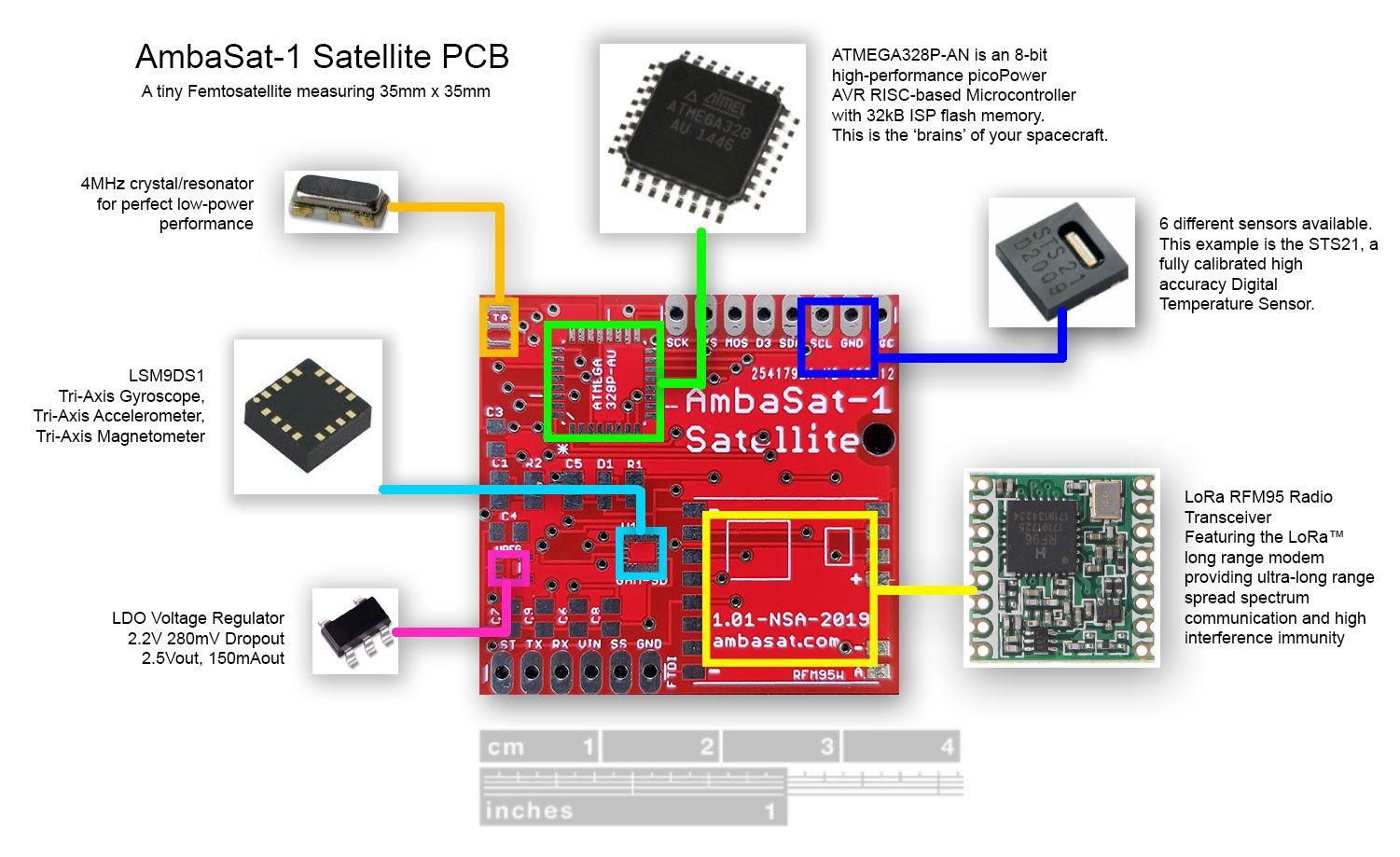

Standardised Flight Trays: AmbaSat-1 ‘ChipSat’ payloads (35 × 35 mm) mount into defined slots on the AmbaSat Flight Trays. Each tray can host up to eight ChipSats, with trays stacked and registered inside the 3U frame on fixed spacers. This gives a known keep-out volume, repeatable alignment and a predictable thermal path from the ChipSat, through the tray, into the CubeSat structure.

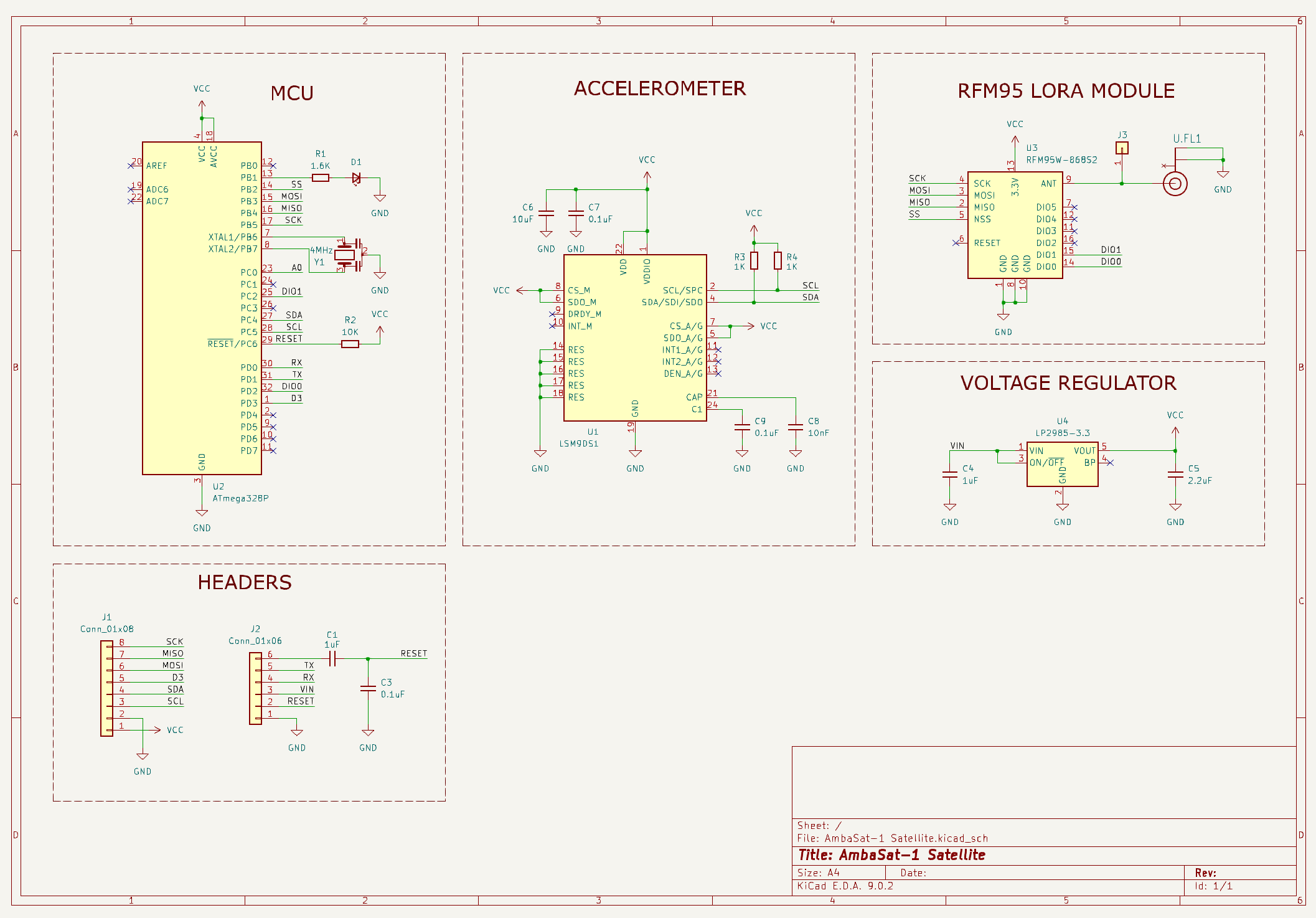

Electrical Interface:

Each Flight Tray plugs into the CubeSat avionics via a defined PC/104 interface, distributing power and data along the stack. At ChipSat level, a standard connector exposes regulated power rails and shared data lines from the onboard microcontroller (I²C plus general-purpose digital and analogue pins). This allows custom or standard sensor boards to be integrated without bespoke harnessing; exact limits and pin-out are defined in the AmbaSat Interface Control Document.

By keeping the mechanical envelope and electrical pin-out stable from mission to mission, the same ChipSat design is re-used across multiple flights. Only the experiment on the PCB changes. AmbaSat manages the trays, CubeSat integration and route to orbit.

The AmbaSat-1 ChipSat is a compact 35 × 35 mm payload card that carries your experiment. Each ChipSat includes the core avionics – microcontroller, power regulation and LoRa radio – so you only need to focus on your sensor and firmware. Multiple ChipSats plug into the Flight Trays, giving a clean mechanical and electrical interface into the 3U platform.

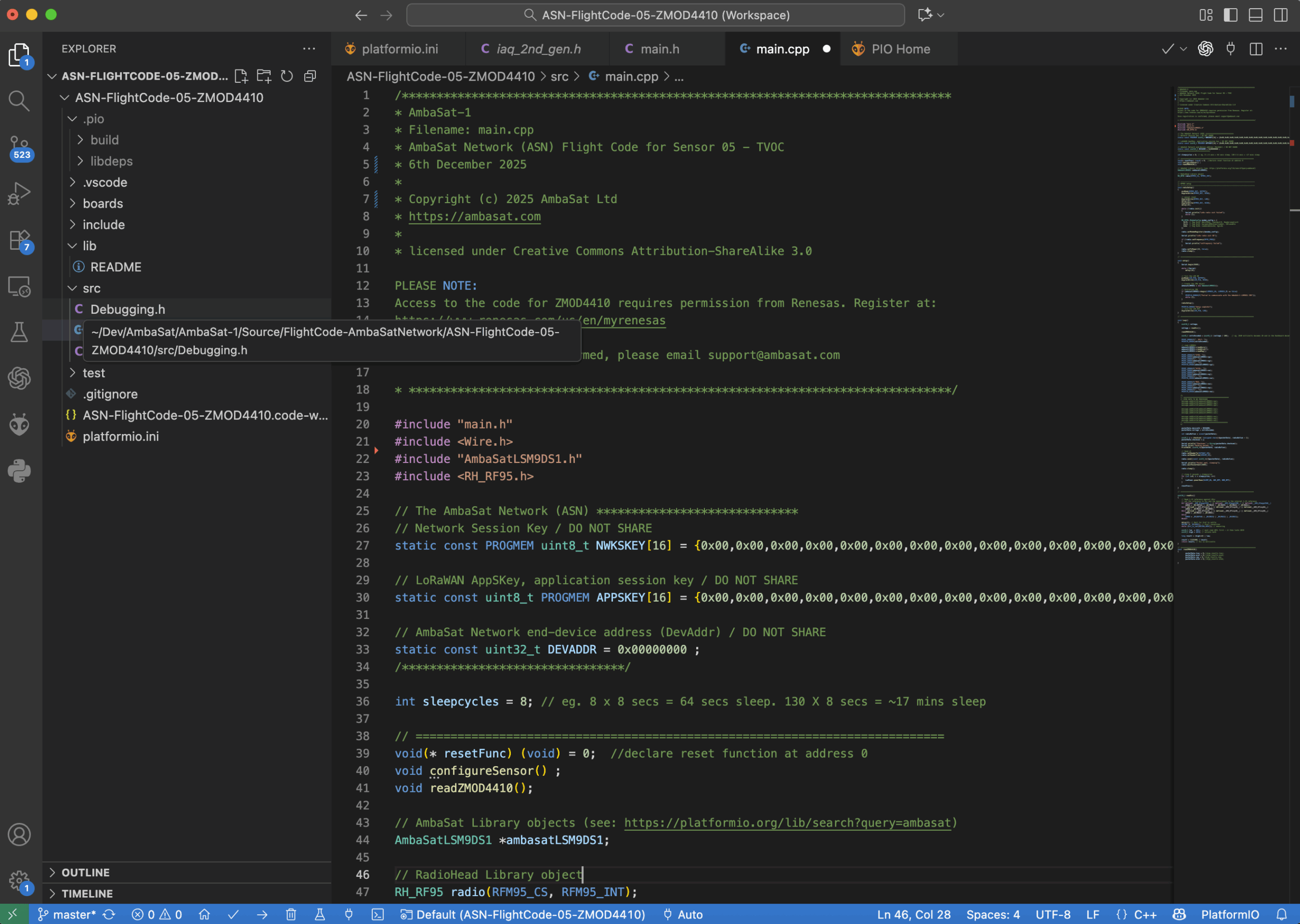

AmbaSat Satellite Coding

ChipSat firmware is written in standard C/C++ using familiar tools such as VS Code and PlatformIO, so your team can work with an environment they already know. AmbaSat provides a reference project for each sensor type, including LoRa communications, power-management and data-packet formatting, so you only need to add your application logic.

Standard toolchain: ATmega328-based platform using mainstream AVR / Arduino-style libraries.

Ready-made libraries: Drivers for approved sensors, LoRa radio and network integration supplied by AmbaSat.

Control over behaviour: You define what is measured, and how your data is packaged for downlink.

Code ownership: You retain full IP in your firmware; AmbaSat reviews and flight-qualifies the build before integration.

In short, you focus on writing and testing the code for your experiment, while AmbaSat handles integration, flight build and operations.

Secure API: All experiment data is accessible via HTTPS REST API, outputting standard JSON format for easy integration into your own analysis tools.

Real-Time Dashboard: Monitor battery voltage, temperature, and sensor logs in real-time via the AmbaSat Mission Control portal.

Data Retention: Full mission archives are stored securely in the cloud for post-mission analysis.

For detailed pinout definitions, mechanical drawings, and thermal constraints, request the full ICD package.